Commercial Gas Pipeline Installation Services

Installing commercial gas pipeline is essential to guaranteeing the smooth operation of numerous enterprises. A professionally built and installed gas pipeline is crucial for every business enterprise that uses natural gas, including restaurants, factories, and other establishments. The importance of commercial gas pipes, the justification for their requirement, the benefits of working with experts like SVD GAS Services, and an outline of the procedure for installing commercial gas pipelines are all covered in this article.

Understanding Commercial Gas Pipelines:

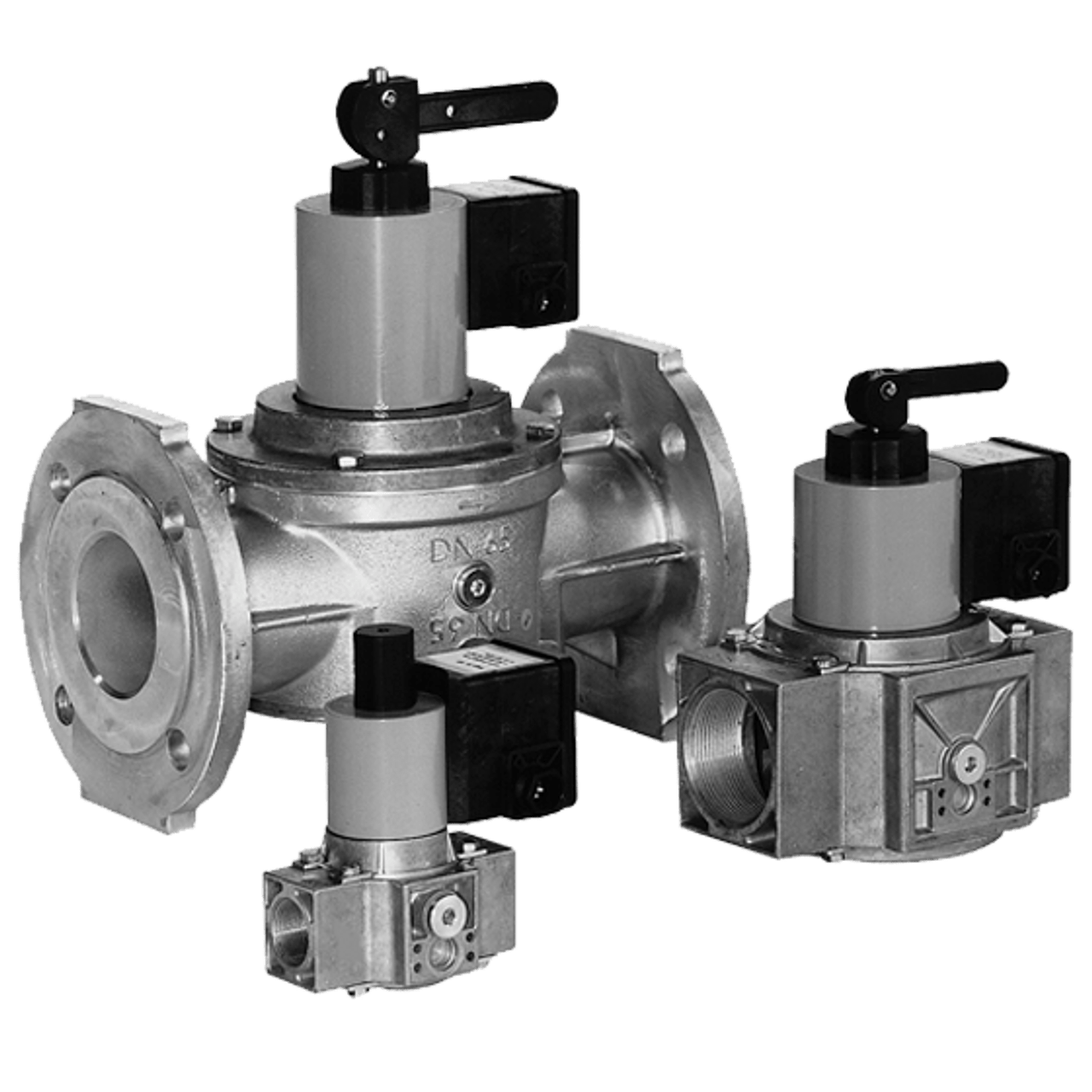

A commercial gas pipeline system is a complex network of pipes and fittings used to transmit natural gas to commercial premises for a variety of applications. These pipelines serve as a lifeline for businesses, supplying a consistent stream of energy for cooking, heating, and powering various equipment. These pipes are designed for efficiency and safety, and are tailored to suit the increased gas flow and pressure needs often encountered in commercial environments.

Importance of Commercial Gas Pipeline Installation:

Dedicated gas pipelines have the potential to considerably benefit companies such as restaurants, hotels, and manufacturing units. For starters, these pipelines ensure a steady supply of natural gas, ensuring ongoing cooking, water heating, and machinery use. Second, such specialized pipes improve safety by reducing the likelihood of gas leaks and subsequent accidents. Finally, they improve cost-effectiveness and operational efficiency by allowing for accurate gas flow management and distribution.

The Expertise of SVD GAS Services:

Engaging the assistance of professionals such as SVD GAS Services is critical for the successful installation of a commercial gas pipeline. This is why:

Process of Commercial Gas Pipeline Installation Services:

SVD GAS Services’ commercial gas line installation process consists of several critical stages:

Inspection:

Once the construction is complete, the pipeline is inspected to ensure that it meets all necessary standards. The inspection process involves checking the quality of the welding, the thickness of the pipeline walls, and the integrity of the pipeline joints. The pipeline is also inspected for any signs of corrosion or damage.

Commissioning:

The commissioning phase of the pipeline installation process involves starting up the pipeline and testing it under operating conditions. This process includes testing the pipeline for leaks, pressure drops, and flow rates. Once the pipeline passes all necessary tests, it is ready for operation.